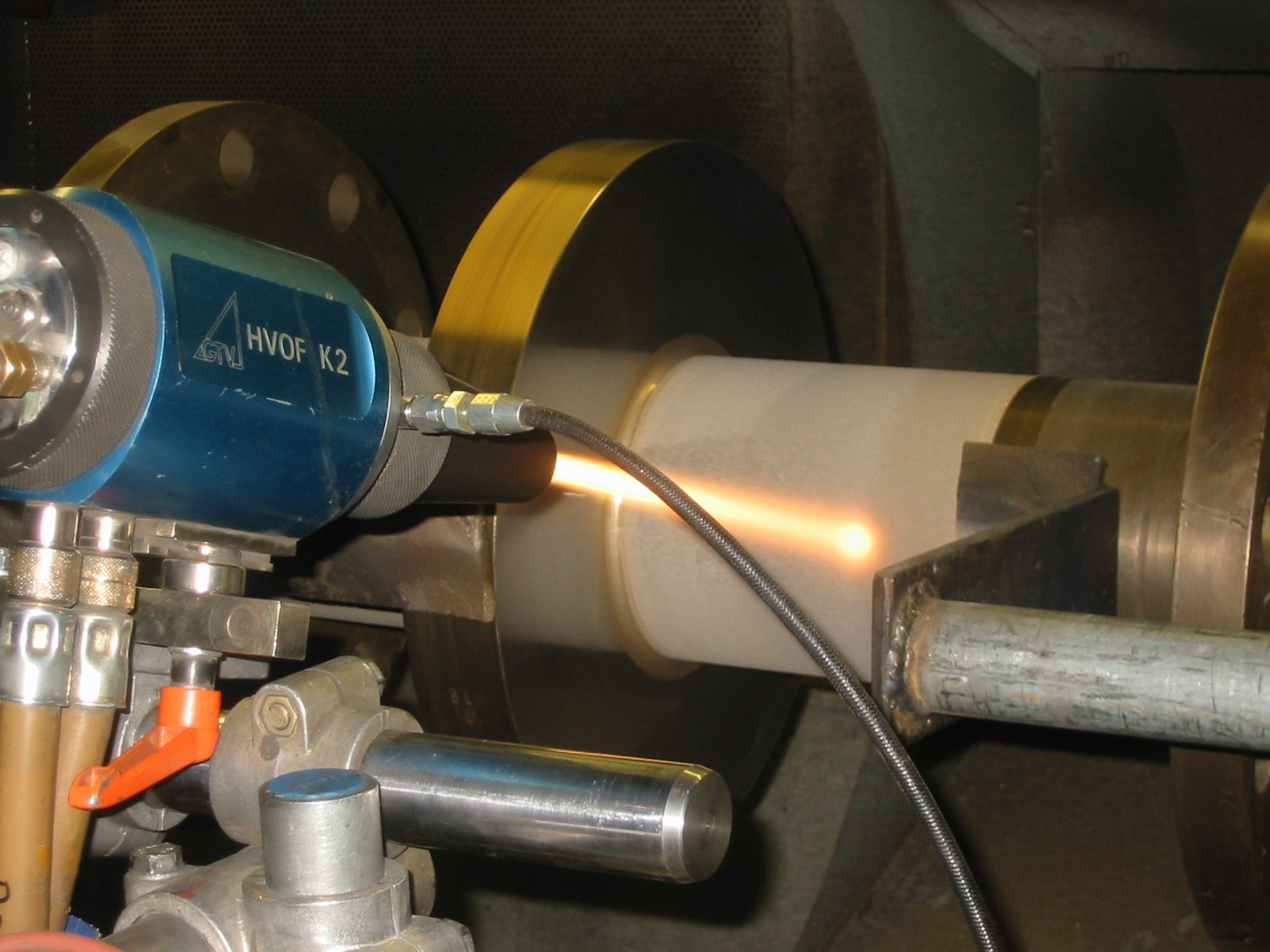

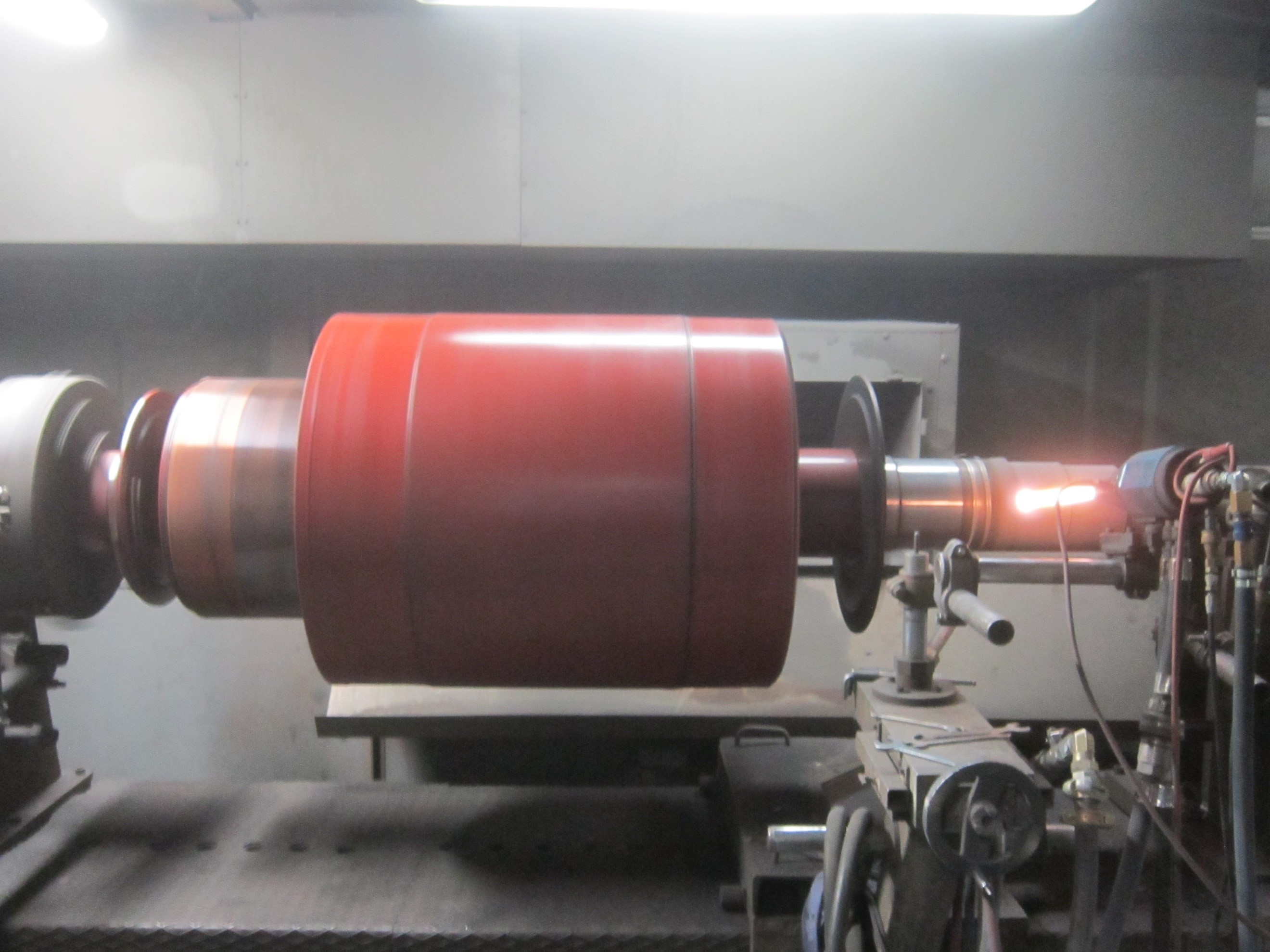

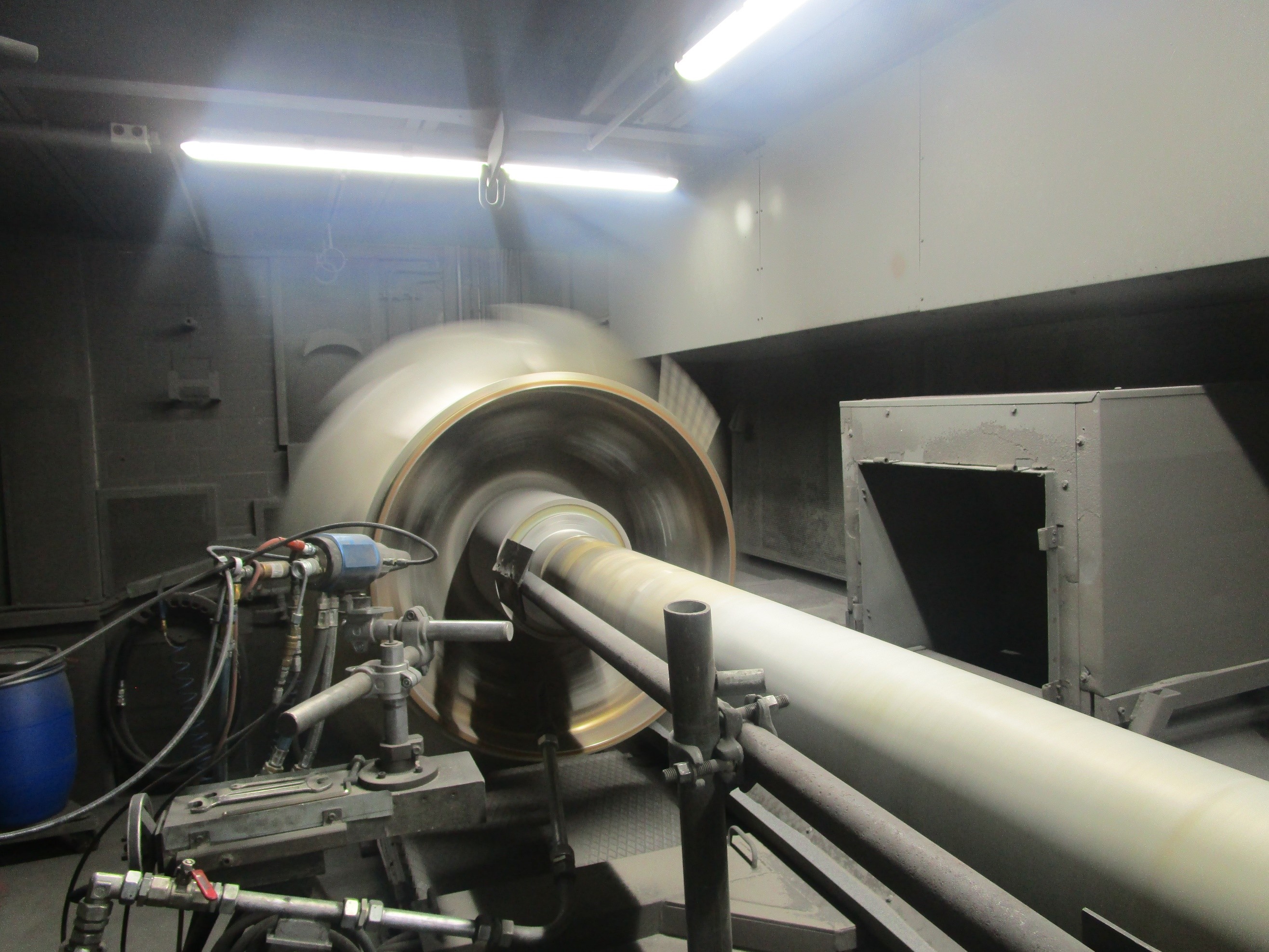

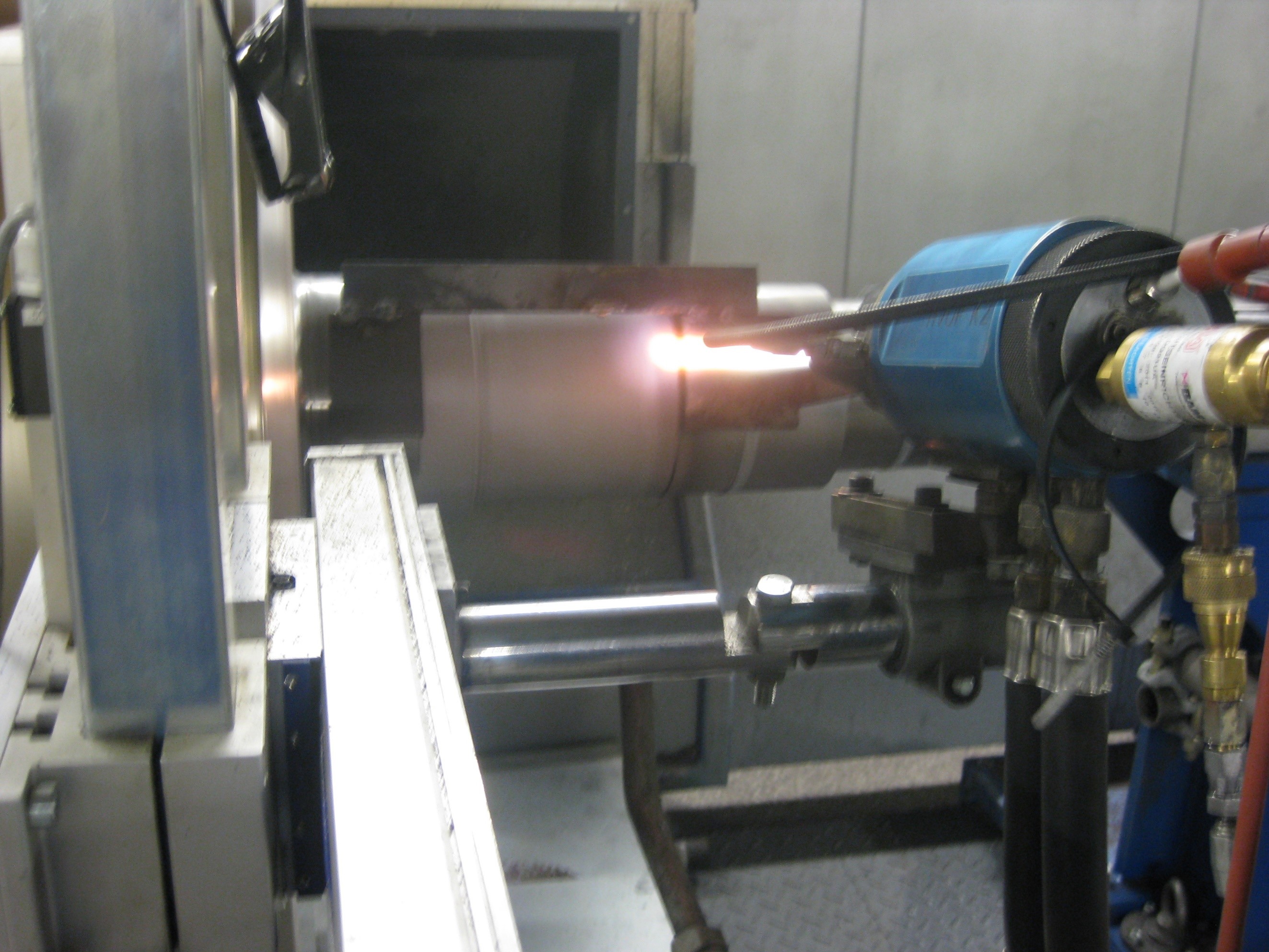

High velocity oxygen fuel spraying (HVOF)

High velocity oxygen fuel spraying involves continuous gas combustion with a mixture of kerosene and oxygen in a combustion chamber. The downstream expansion nozzle generates flow velocities in the gas jet of approx. 2500-3000 m/s, resulting in extremely dense spray coatings with excellent adhesion properties.

The spray material is melted in the flame and impinges on the component at a speed of approx. 600-700 m/s. High-quality, hard, very dense and highly wear-resistant coatings are produced.

Examples of coating materials:

- Tungsten carbide

- Tungsten carbide-cobalt chrome

- chromium carbide-nickel chrome

- Nickel chrome

- etc.

Keywords:

- Coating possible on almost all base materials .

- hard coating

- low heating of the base material

- external and internal coating

- coating to size possible

Contact Persons

Hamburg

Mr. Rene Schulze

Phone: 040 / 75 60 10 33

Rostock

Mr. Michael Müller

Phone: 0381 / 60 90 7 580

Location Hamburg

Buschwerder Winkel 2

21107 Hamburg

Tel.: 040 / 75 60 100

(24-hour on call)

Fax: 040 / 75 34 025

E-Mail:

Location Rostock

Am Liepengraben 7a

18147 Rostock

Tel.: 0381 / 60 90 7 0

(24-hour on call)

Fax: 0381 / 60 90 7 44

E-Mail: