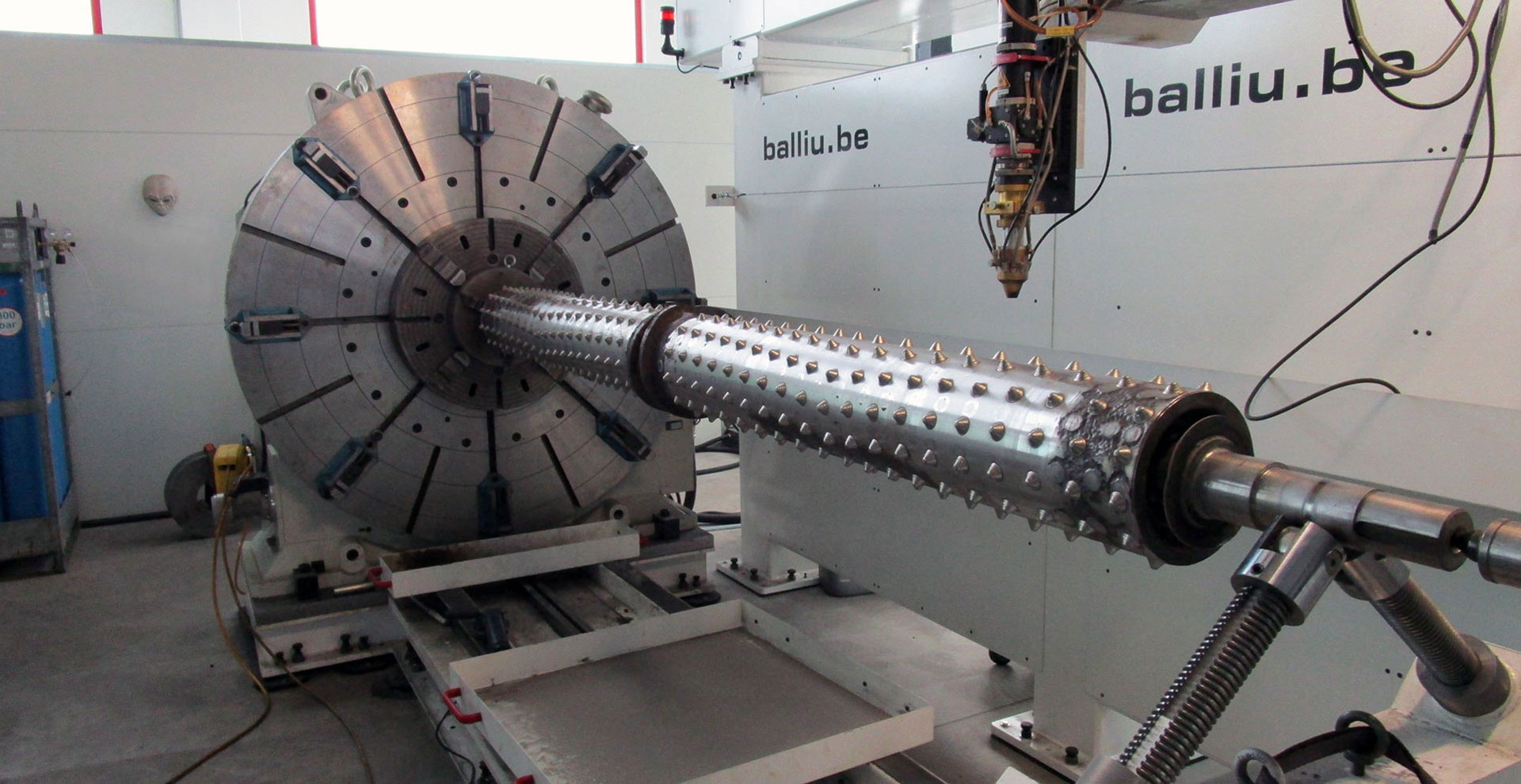

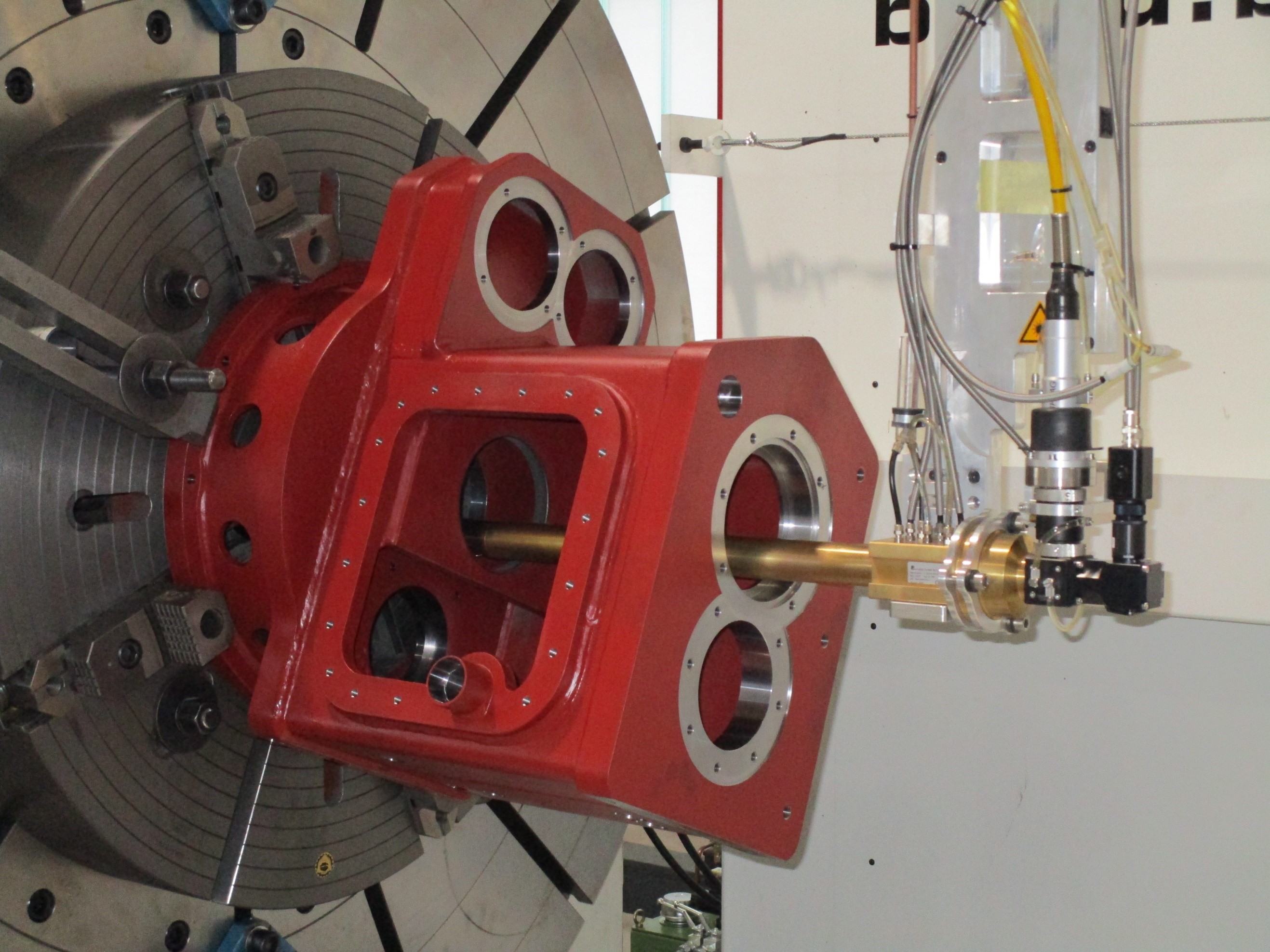

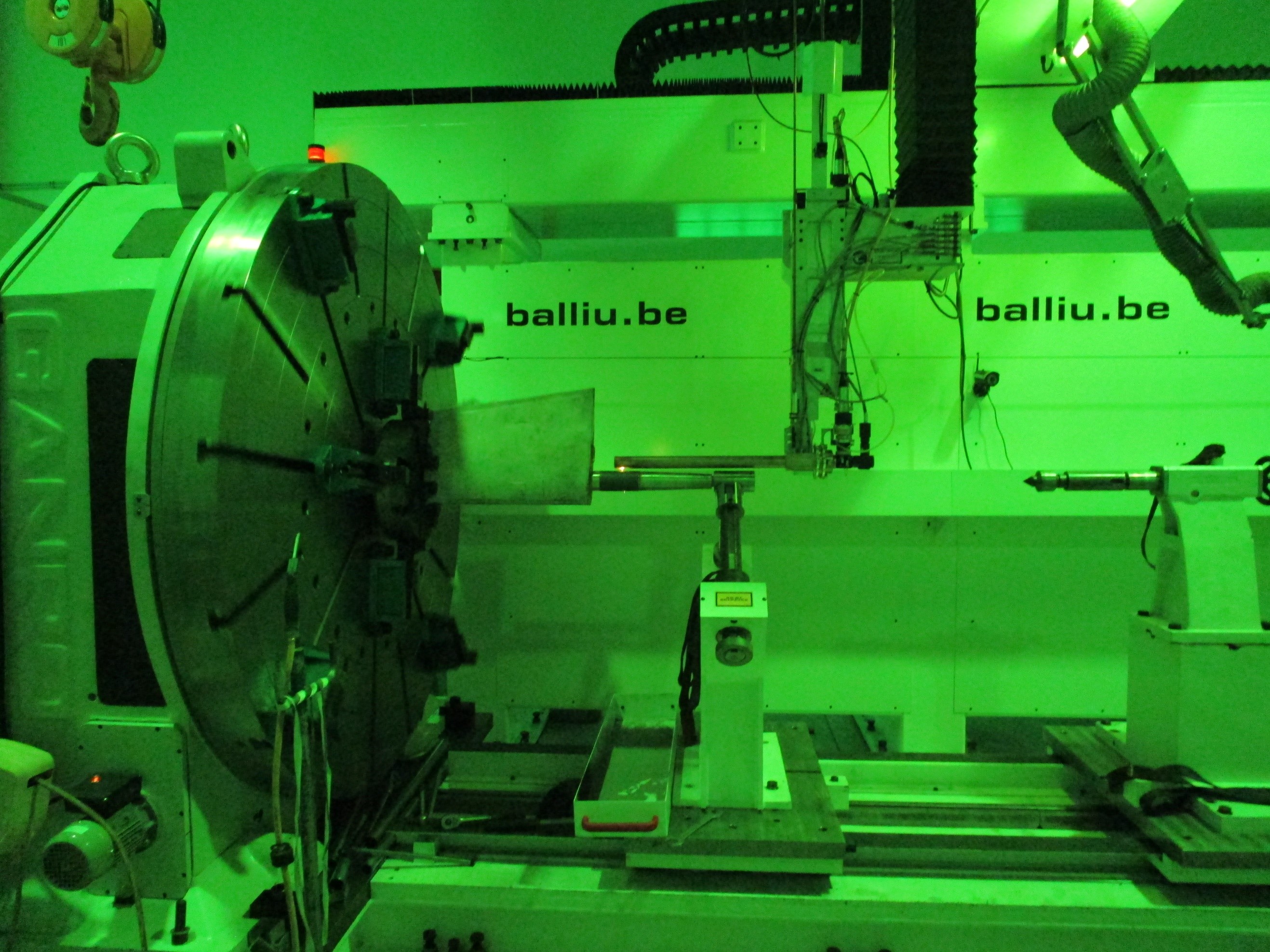

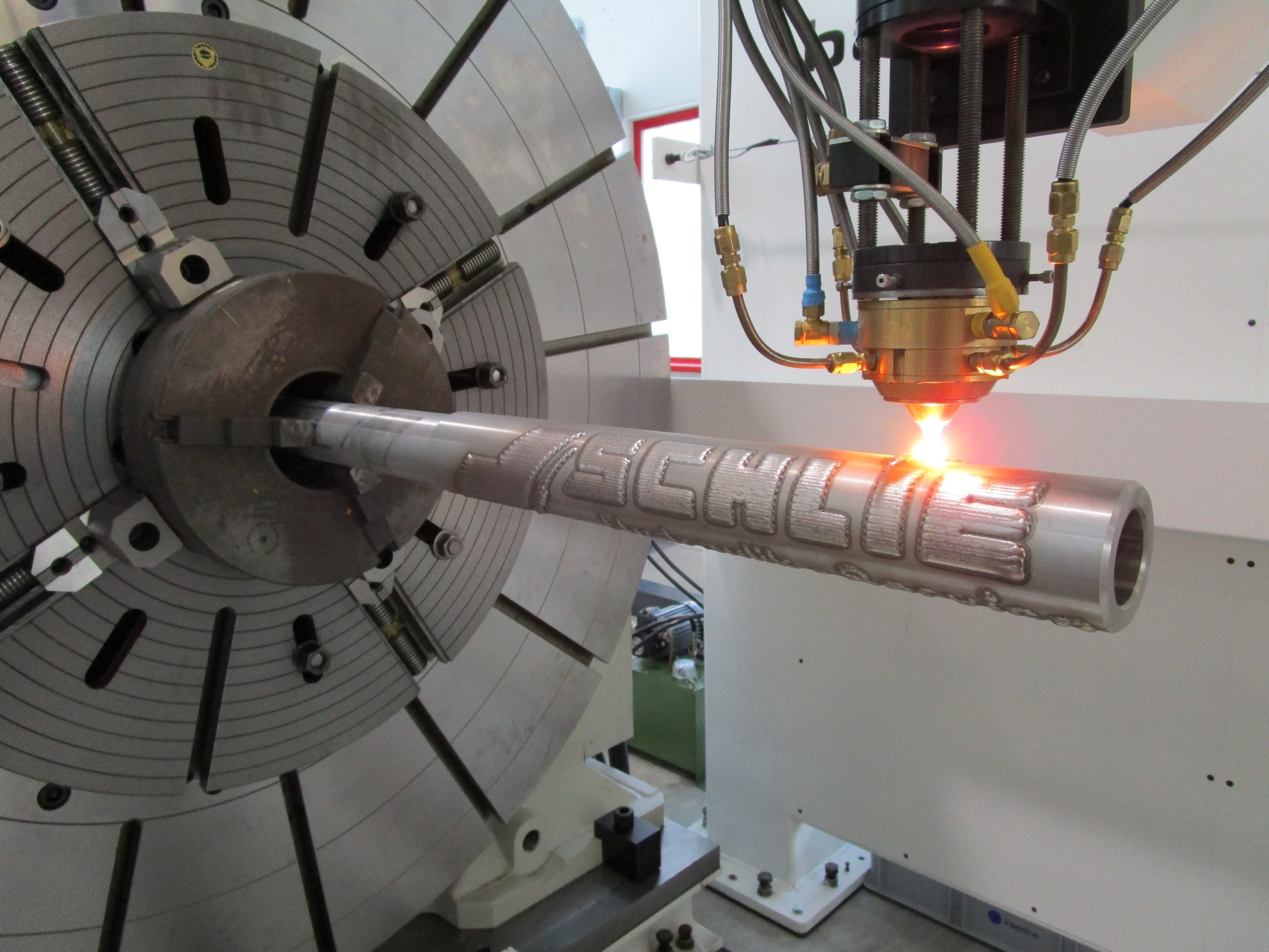

Laser cladding

Laser cladding is a process in which a surface is applied to a workpiece by means of spot melting and simultaneous application of almost any material. This is done in powder form, e.g. as metal powder. In laser cladding, the laser heats the workpiece selectively and melts it locally. At the same time, an inert gas mixed with fine metal powder is fed in. The metal powder melts at the heated spot and bonds with the metal of the workpiece. There is little mixing of the base material.

The laser cladding process is fully automated and is monitored only by a system operator.

Examples of coating materials:

- Inconel 625

- Stellite 6

- Stellite 21

- usw.

Keywords:

- melt bond

- homogeneous microstructure

- contour-accurate cladding

- CNC controlled

- combination with other coating processes

Contact Persons

Hamburg

Mr. Rene Schulze

Phone: 040 / 75 60 10 33

Rostock

Mr. Michael Müller

Phone: 0381 / 60 90 7 580

Location Hamburg

Buschwerder Winkel 2

21107 Hamburg

Tel.: 040 / 75 60 100

(24-hour on call)

Fax: 040 / 75 34 025

E-Mail:

Location Rostock

Am Liepengraben 7a

18147 Rostock

Tel.: 0381 / 60 90 7 0

(24-hour on call)

Fax: 0381 / 60 90 7 44

E-Mail: